JIFMAR SCOTLAND offers integrated maritime solutions by offering cutting-edge services in the maritime and offshore fields. Their dedicated team has been supporting an installation project on Gouthwaite Reservoir alongside Yorkshire Water and local sub-contractors.

The project that started in July 2023, which has included creating a bypass of a dam by installing 80 metres of DN2000 pipe under water that initially was installed via excavation and float and sink methods; however, issues arose during a failed pressure test.

During the installation the team found issues with leaking joints as water was coming through the flanges on the pipeline, because of the intense weight and pressure.

Due to the timescales, the expense of labour and equipment, and the difficult access outside of the pipe, continuing to excavate on site was not an option as this project needed to be completed quickly and with minimal disruption – resulting in the need for a trenchless method to be used.

JIFMAR SCOTLAND, made contact with S1E Ltd, Specialist Supplier in Trenchless Technology as they were recommended the mechanical seal solution Quick-Lock, from UHRIG Group. The Quick-Lock systems are global proven solutions to seal pipes and its design and trenchless installation methods made it compliant with the water authority’s requirements for an ecofriendly solution.

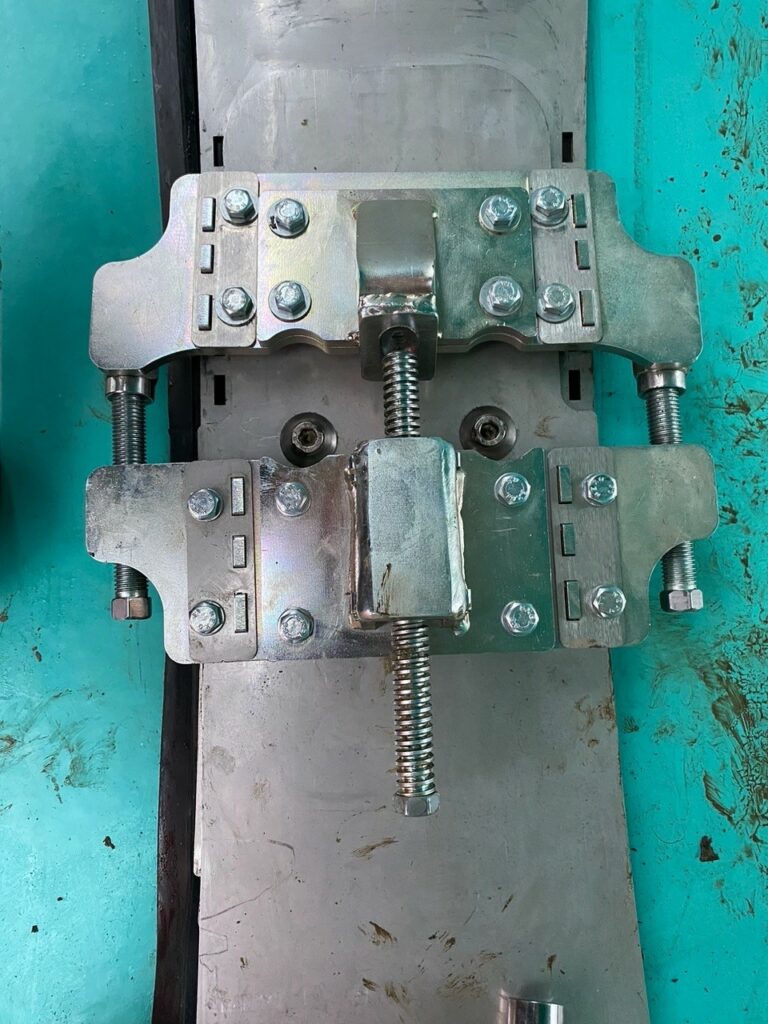

As a certified Quick-Lock partner and the only UK official stockist and reseller, S1E Ltd worked with JIFMAR SCOTLAND so they had all the support, technical data, and equipment they needed for the repair, as they helped supply and deliver eleven of the new designed Quick-Lock BIG systems to site.

The installation of the Quick-Lock BIG systems was under challenging conditions due to there being little to no more than 20cm of visibility when under water and inside the pipeline. Each mechanical seal needed two divers as they placed one mechanical seal on each flanged connection. Prior to installation, training with the divers took place above ground, which included blindfolds to try and replicate the unfamiliar working conditions, as well as preparing the seals with buoyancy aids to help with transportation in the water and inside the pipe.

The Project Manager at JIFMAR SCOTLAND, commented:“We were up against timescales, and needed to find a resolution that didn’t require anymore further work outside of the pipe. It’s fantastic we were able to find a simple solution in Quick-Lock so we could complete this project on schedule. The Quick-Lock BIG’s swift installation process enabled our team to create a watertight seal on the leaking joints easily.”

He continued:“S1E not only helped supply the solution but supported us throughout the process, both in the initial scoping phase and installation, with good communication, advice and of course, fast delivery.”

Quick-Lock mechanical point repair systems are made from high-quality and long-lasting materials, such as EPDM rubber and stainless steel. Their install requires no curing time and releases no emissions or foul smells and doesn’t involve excavation which helps reduce disruption and avoids additional equipment rental charges.

The systems are an efficient method of sealing pipes that are damaged due to corrosion, displaced joints, tree roots and ground movement, and are manufactured to suit an array of pipe materials including concrete, steel, cast iron, plastic, and glass-fibre.

Christopher Rings, Sales & Customer Service Europe at UHRIG Kanaltechnik GmbH, said:"It’s been great to work with both S1E and JIFMAR on this very unconventional project, and see its success. Our new designed Quick-Lock BIG system is far easier to install and has shown to be more efficient in this instance when working in such challenging conditions. We are looking forward to continuing to support our users and work in partnership with S1E and their customers.”

Quick-Lock BIG was designed for the renovation of individual damages in walkable and large diameter pipe systems up to DN 3000 and includes a reliable EPDM rubber seal with sealing technology that has a long-life expectancy and very high resistance.

Mechanical point repair systems have been used thousands of times globally, however it continues to be unknown to some contractors in the industry as a trenchless solution. Trenchless systems can reduce costs by 40%-60% and result in fewer disturbances to the public and the environment when compared to excavation methods.

S1E Ltd supply certified and quality mechanical point repair systems from UHRIG in form of their Quick-Lock range – the standard range includes sizes from DN150 -DN800. Other sizes are available in the Quick-Lock Mini, Quick-Lock BIG and Quick-Lock Flex ranges. Quick-Lock Liner end seals are also available, to seal the gap between a CIPP liner and the host pipe. If you have any queries feel free to contact us, as one of our experienced sales team members will be happy to help. Contact the S1E Sales Team on 01226 397015 or email contact@s1e.co.uk.