Lanes Group plc, the UK’s leading drainage and maintenance service provider, has completed a critical pipe rehabilitation project at the swimming pool of a large holiday park using a new brush coating lining system.

This project was an integral part of the comprehensive renovation of the pool facilities aimed at enhancing the guest experience and ensuring long-term operational efficiency.

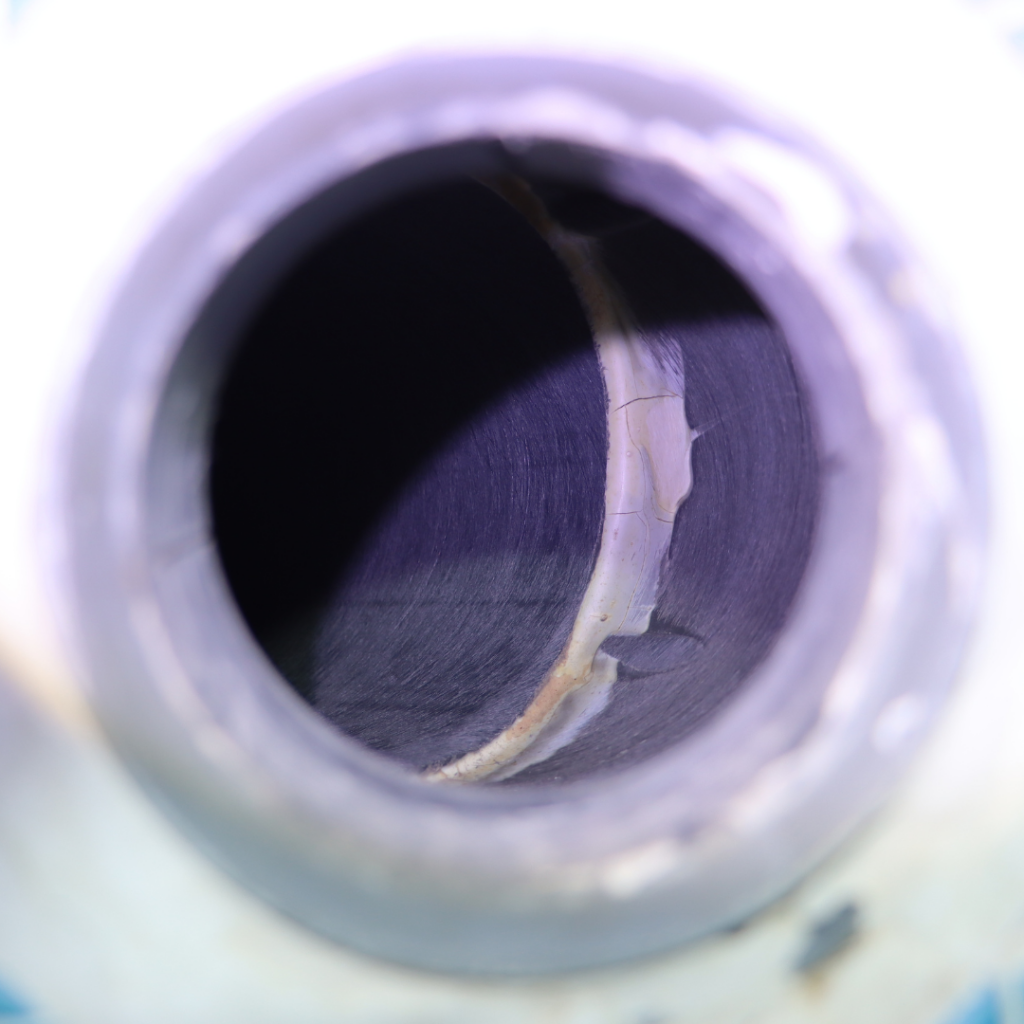

The swimming pool, was undergoing a significant renovation when it was discovered that the pool’s piping system was suffering from water leaks and corrosion.

The primary problem was the chlorine in the water, which had caused substantial wear and tear over the years. To address these issues, Lanes Group was contracted to rehabilitate the pipes, ensuring the pool’s reliability and safety for years to come.

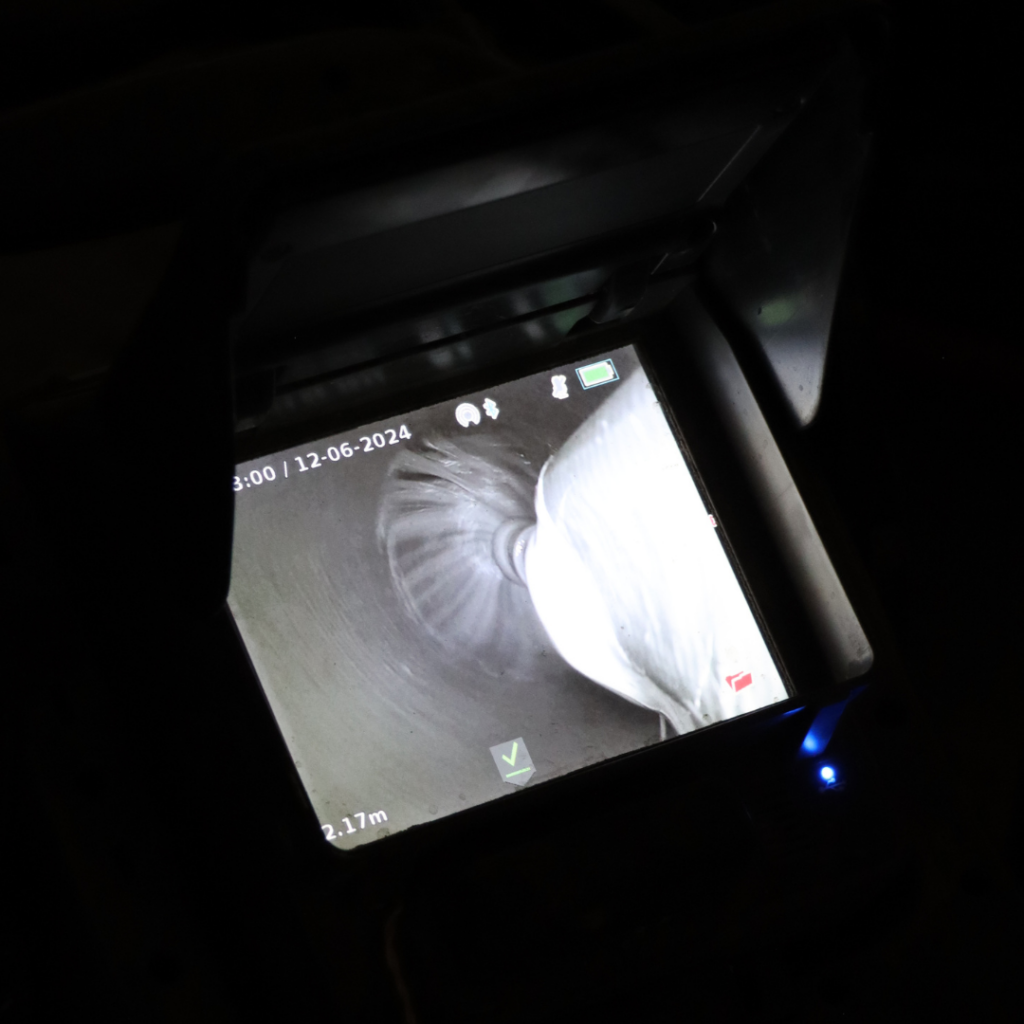

A CCTV pipe survey, of six sets of four pipes between 2-4 metre long of DN100 was carried out with a maximum of five bends. This confirmed corrosion and cracks were causing water leaks and chlorine build-up along the swimming pools pipe network.

Due to multiple bends in the system and with no option to excavate and replace the pipes, the challenge was to find a cost-effective repair method suitable for operations to be carried out quickly to meet project deadlines.

To carry out the pipe rehabilitation, Lanes Group discussed with S1E Ltd, a specialist supplier in trenchless technology, the no-dig methods that could be used.

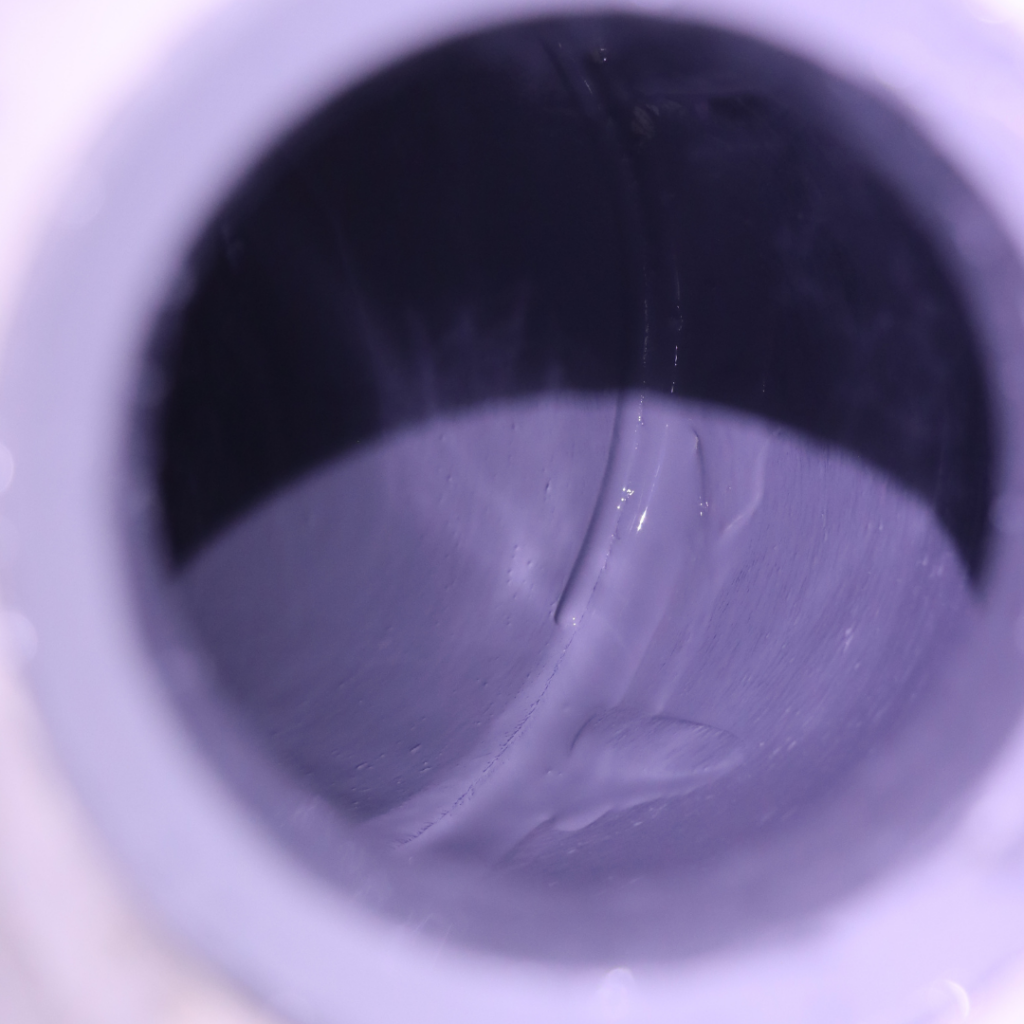

Working collaboratively with Picote Solutions, the decision was made to use the new state-of-the-art Xpress Brush Coating system from Picote Solutions. This innovative technology was chosen for its effectiveness in providing a durable, long-lasting solution to pipe corrosion and leakage.

The new brush coating system provides faster curing times, no waste, less mess, and minimal setup time for revolutionary cost and time savings.

Gary Carey, Project Manager at Lanes Group plc, said:“We are extremely proud of our team’s successful execution of the pipe rehabilitation project. The use of Picote’s Xpress Brush Coating system allowed us to address the issues found in the swimming pool and ensured a durable and long-lasting solution but with minimal disruption to the resort’s renovation operations.”

He continued:“The collaborative support from S1E and Picote was invaluable, providing us with the expertise and resources needed to deliver a project to the highest of standards. We look forward to seeing guests enjoy the newly renovated pool facilities for many years to come.”

The Xpress Brush Coating system offers several key features and benefits:

Lanes Group worked together closely with S1E and Picote Solutions throughout the project. S1E and Picote provided comprehensive support; providing training on the equipment prior to starting the project as well as onsite support, and supplying the necessary equipment and resin for both the preparation and rehabilitation stages. Their expertise and hands-on assistance were invaluable in ensuring the project was completed to the highest standards.

The confined space and access, as well as the temperature of the building and working on an everchanging site with other contractors, made the location a challenging place to work.

However, due to the flexibility of the Picote Xpress Coating Kit, and its quick application process, the team from Lanes Group successfully rehabilitated 14 full length pipes in total.

Working in set of four batches, the team worked efficiently to apply multiple coats to all 24 pipes, to complete the work in seven days.

Andy Kibblewhite, Senior Technician Trainer, Picote Solutions commented:“Our team was thrilled to collaborate with S1E and Lanes on the pipe rehabilitation project. The new Picote Xpress Coating System is the next generation of brush coating for DN32-300, to renovate old or deteriorated drains and sewers to prolong the lifespan of an existing pipe.”

“Our onsite assistance ensured that the Lanes team could apply the coating effectively, addressing the pool's pipe corrosion and leaks with precision. It was satisfying to see the project come together smoothly and to know that the pool facilities will be significantly improved."

The rehabilitation of the swimming pool pipes was completed successfully and on schedule to the operations project timescales, much to the satisfaction of the client. The newly coated pipes now offer enhanced durability and reliability, ensuring that guests can enjoy the swimming pool without interruptions.

Dave McCarthy, CIPP Lining Develop Manager at S1E added:“It’s great to have been a part of this project with both Picote and Lanes Group. The results on site the team gained from using the new Picote Xpress Coating System, have been outstanding. We believe it will be a game changer to the drainage industry, and we look forward to continuing to offer our services in providing leading trenchless technology alongside our partners.”