Description

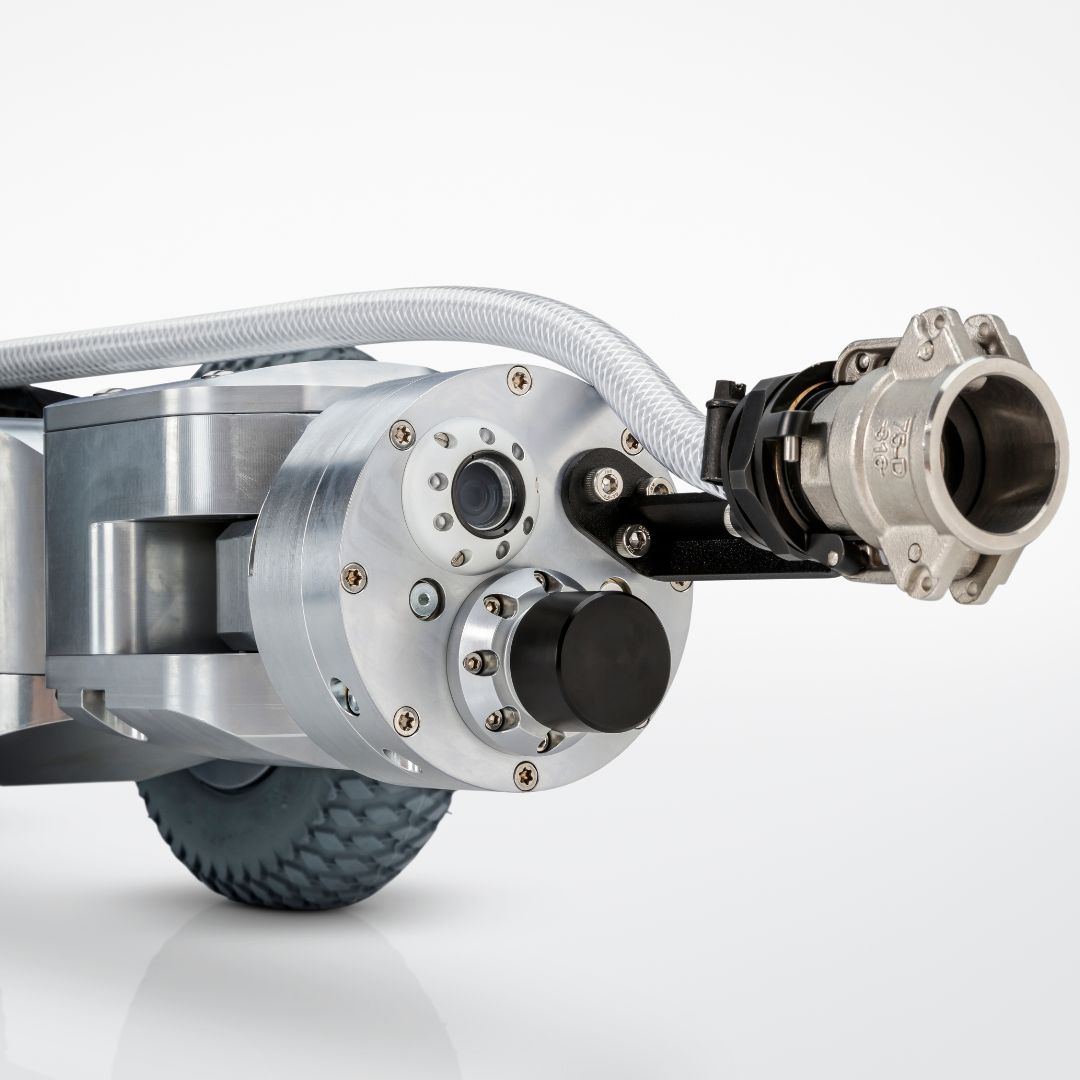

S1E Limited distributes robotic cutters from German manufacturer, IBAK. The MicroGator® Air pneumatic drain cutter from IBAK is equipped with a powerful compact motor. This pneumatic cutting robot is designed for main sewers from DN200 (relined) to DN800.

The system was designed for compatibility with the IBAK MainLite camera system, so components such as IBAK control units and winches are ideal for use with it. The MicroGator® Air is compatible with Schneider cutting tools, offering a huge range of especially designed cutting heads. It comes complete with heads for liner and concrete removal. The MicroGator® Air is equipped with a CutterCam, always offering a clear view and the best possible orientation. The drain cutter features a 4th axle to tilt the head forward, a lowering device for easy placement into the manhole and permanent pressure monitoring.

The MicroGator® Air can be supplied as a portable cutter or mounted within a van. The MicroGator® Air is an ideal solution for service providers who are looking for a compact cutting system and at the same time want to benefit from the advantages of a complete inspection system.

Surveys:

- Tilt measurement: Assists in locating possible underbends and helps in hydraulic calculation of the sewer network.

- Diameter determination: Used to determine the diameter and to correct or complete data. Helpful for detecting cross-section changes, e.g. to better plan rehabilitation measures.

- Pipe run: Serves to correct or complete sewer network data and is thus helpful for better construction and rehabilitation planning.

- Pipe profile analysis / deformation measurement: Used during new construction inspections, for rehabilitation planning and early detection of changes in the pipe profile to prevent damage.

- Damage survey: Serves to determine and measure damage to the pipe wall and protruding objects on the basis of common standards and regulations.

- Temperature measurement: Assists with landfill hazard mitigation and engineering design.

Comfort and efficiency features:

- Flexible focus: The camera focus can be flexibly adjusted to areas at different distances.

- Powerful air motor: Thanks to optimized compressed air supply, high cutting performance is achieved.

- Long range: Very good traction combined with a lightweight supply cable allows up to 300 m to be covered effortlessly.

- Clear view through air shield: A permanent air flow keeps the optics of the observation camera clear.

- Cutter interchangeable head system: Faster and easier exchange of cutter heads to suit various applications and materials.

- Complete inspection: Inspections are possible with the same operating system and cable winch.

- Pressure monitoring: Ensures operational safety and function control.

- Stability control: Sensors in the robot and in the camera provide stability.

- Combination: Inspections are possible with the same operating system.

- Functional diversity: Additional rehabilitation and inspection tasks can be handled by suitable accessories.

- Noise protection: With regard to the noise level, the compressors required for operation comply with the occupational health and safety requirements and allow optimum communication and productivity during operation without additional noise protection.

- Ergonomics: IBAK systems are designed for permanent, professional use and meet or exceed the respective specifications and guidelines for ergonomics.

- Modular structure: All components of a system can also be subsequently configured to the respective application.

- Energy supply: Has its own energy supply and is independent of an external energy source. Use of the latest battery technology incl. integrated battery management system.

Note on the system configuration shown: The range of functions varies depending on the selected system configuration.