Description

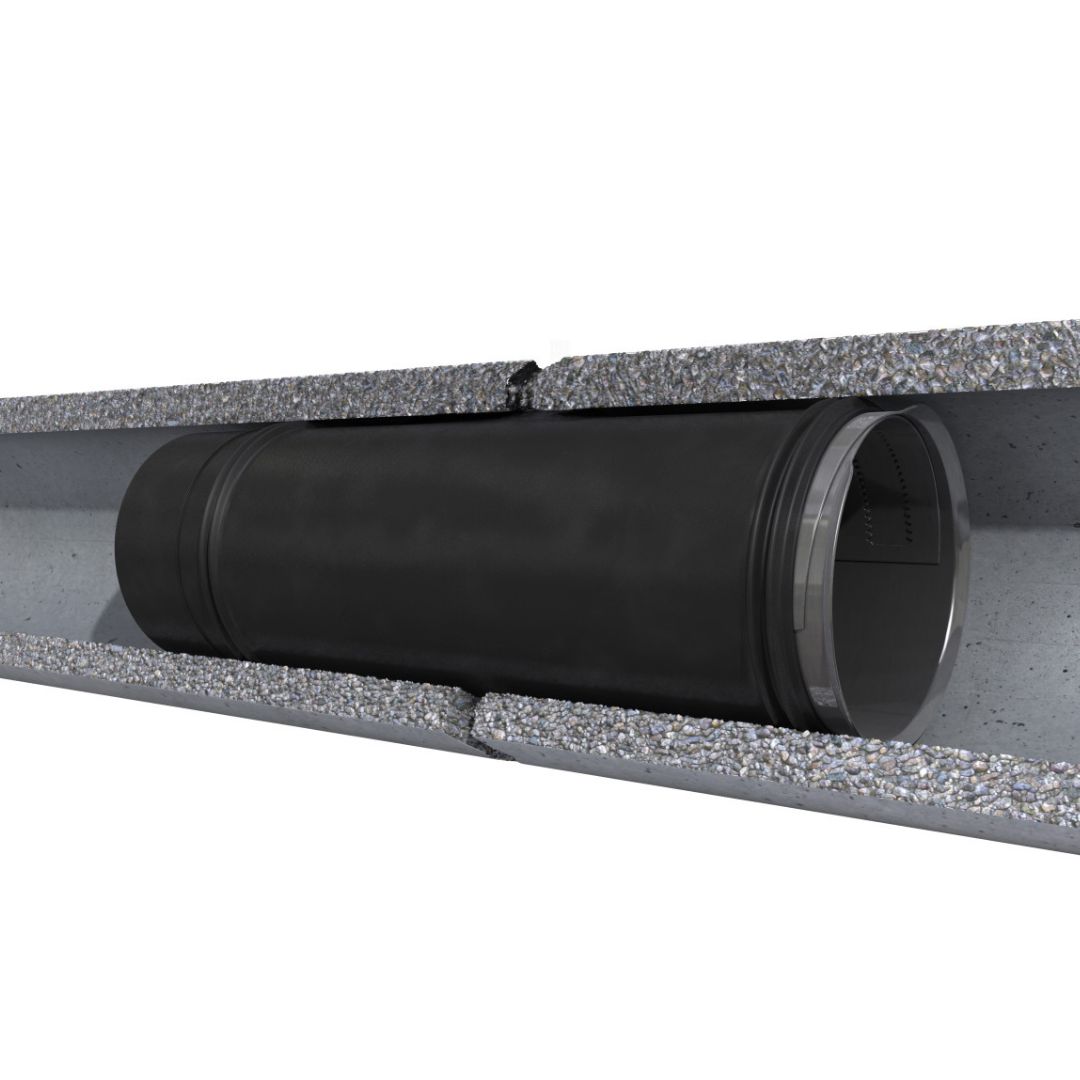

The Quick-Lock Standard system is a revolutionary sleeve solution for trenchless pipe repair, offering quick and effective sealing of cracks, leaks, and joint displacements in pipelines. Designed for durability and ease of use, this system provides a permanent mechanical seal, restoring structural integrity without the need for costly excavation.

The robust stainless-steel sleeve and EPDM rubber gasket ensure long-lasting performance in a range of pipe materials, including concrete, steel, clay, and PVC. Quick-Lock is suitable not only for sewer line repair, but also for potable water, seawater and industrial applications.

Successfully used for many years as a repair procedure for closed sewer renovation. The Quick-Lock system seals damaged pipes mechanically, without chemicals and regardless of the pipe material. Using the patented Quick-Lock locking system, a secure seal of the EPDM rubber to the pipe is guaranteed. Once in position, the Quick-Lock absorbs movement within the pipeline, maintaining the seal. For longer areas of damage, Quick-Lock sleeves are used in series one after the other.

For fast, efficient, and cost-effective pipeline repairs, Quick-Lock system is certified by WRc, DIBt, and ASTM, and NSF for potable water applications.

Quick-Lock is a seamless assembly system for localised repairs.

- Swift and simple installation process.

- Long-lasting materials: 1.4404 (316L) stainless steel with EPDM rubber as standard.

- NBR rubber available on request, or special KTW-approved seal for drinking water applications.

- Resistant to high-pressure jetting in accordance with DIN 19523.

- Low investment in system technology.

- Portable equipment for hard-to-reach sites.

- Can resist high internal pipe pressure when installed.

- Can be used for point repair prior to linings.

Quick-Lock installation equipment is available to hire as well as purchase. Call the team on 01226 397015 or email sales@s1e.co.uk to discuss your requirements.

Specification

Materials

Quick-Lock’s constituent materials, 316L stainless steel and EPDM seal, have proven themselves in pipeline construction for decades. Grade 316L stainless steel lasts virtually forever in municipal wastewater

The EPDM seal is a state-of-the-art pipe engineering product with a high service life and extremely high wear resistance.

In the case of special applications in industrial settings, refineries, or seawater, we can supply you with a stainless-steel sleave in special alloys upon request. In addition, we also offer an NBR-quality seal for applications involving oil, grease, and hydrocarbon. For potable water applications, we offer a KTW-approved potable water seal.

Product range

The Quick-Lock sleeve is available in two configurations:

- Variant 1: Length 400mm, diameter DN 150–400 / 6”–16”, internal pressure 25 bar /262.59 psi, external pressure 1.5 bar / 21.76 psi

- Variant 2: Length 500mm, diameter DN 450–500 / 18”–19”, internal pressure 25 bar / 262.59 psi, external pressure 1.5 bar / 21.76 psi. Length 500 mm, diameter DN 600 / 23″, internal pressure 0,75 bar / 884.73 psi, DN 700 / 28″, internal pressure 0,5 bar / 72.51 psi and DN 800 / 32″, internal pressure 0,3 bar / 43.51 psi

When using the Quick-Lock sleeve (non-walkable area) in pressure pipelines (internal pressure), pressure resistance can always only be guaranteed in conjunction with the use of a protective plate around the outside of the seal. The protective plate prevents the seals from being displaced into any gaps or fissures in the pipe.

For us to be able to guarantee quality service, it is essential that you use Quick-Lock installation packers to install the Quick-Lock sleeves. In the case of non-standardised internal pipe diameters, we can offer you a wide range of special solutions. If you need to rehabilitate a pressurized pipe, we are happy to give you individual advice. A perforated Quick-Lock sleeve is available for damage in drainage or filter pipework.

Shipping Information

Please note that the delivery estimates provided below are intended as a guide only. Please contact the S1E Team if you have specific deadlines or requirements.

For online orders:

Collection:

- From noon on the day of order, if the order is placed by 11am (Mon – Fri)

- The next working day following order placement, for orders placed after 11am (Mon – Fri)

- Opening hours for collection 0730-1700 (Mon-Thurs), 0730-1600 (Friday).

Deliveries to UK Mainland:

- Despatch on day of order placement if order is placed by 1pm (Mon-Fri), delivery next working day (Mon-Fri), not guaranteed.

- Despatch the next working day after order placement, if placed after 1pm (Mon-Fri), delivery in 2 working days (Mon-Fri), not guaranteed.

Deliveries to Northern Ireland:

- Despatch the next working day after order placement, if placed after 1pm (Mon-Fri), delivery in 2-3 working days (Mon-Fri), not guaranteed.

- Orders shipped to Northern Ireland are based on the weight of the items ordered up to 70kg.

- For orders over 70kg please contact our Sales Team directly on +44 1226 397015 or sales@s1e.co.uk for further advice.

More information