Please note we are closed on Friday 18th April 2025, and will be back open Tuesday 22nd April 2025. Any orders placed after 1pm Thursday 17th April 2025 will not be dispatched until Tuesday 22nd April 2025.

Please note we are closed on Friday 18th April 2025, and will be back open Tuesday 22nd April 2025. Any orders placed after 1pm Thursday 17th April 2025 will not be dispatched until Tuesday 22nd April 2025.

We all got past the big freeze last month, but who is to say another one will not be coming again soon? Periods of cold weather followed by warming occur every winter for us in the UK, and over the years water companies have continued to learn from each winter to successfully manage these winter freezes with little-to-no customer impact; and with a special thanks to emerging tools and technology in trenchless pipeline repair.

Climate change is increasing the risks of extreme weather variability during the winter, so it’s clear there is a need to be prepared as a business within the water and drainage industry to ensure good continuity of service for your customers.

We don’t need to tell you drainage experts about the build-up of snow and ice, and when it melts the risks and substantial problems it can cause to drainage systems. All that extra pressure and any drainage system that was not functioning properly in the first place, will be at risk of cracking or blockage – so, what are you using to fix your cracked pipes?

Pipes that are cracked or become displaced end up being a bigger problem if left unrepaired and then the next thing you know, it’s no longer a trenchless repair and the cost starts mounting up. One of the best ways to tackle the issue of a cracked pipe from those winter issues is a patch repair system to reline the pipe and create a professional, watertight repair to the localised areas of damage. Applying a structural patch repair with a system such as our Pipe Doctor Repair Kits, will improve the flow of water and reduce the risk of the pipe cracking further and potentially collapsing.

Structural patch repairs are a curing system using a mat pre-cut to the required size of the crack and a resin formulation – You can find out more information on our WRc-approved Pipe Doctor Patch Repair Kits on our website, which are also available in Summer, Winter or Rapid resin formulations to help with curing times while on-site, for example, using the winter resin formulation in cold temperatures will cure faster than using a summer resin mix.

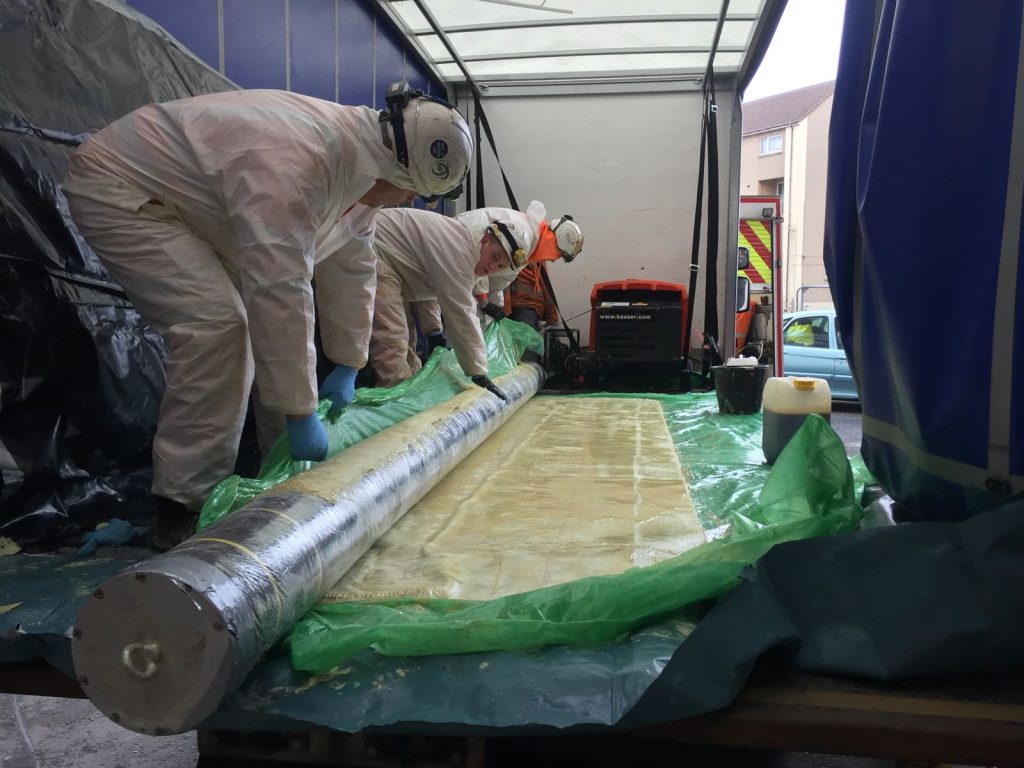

A winter-formulated resin will help your curing process, but we know curing in extremely cold conditions can be challenging, therefore when trying to effectively install a CIPP liner in cold work environments, it is important to think about controlling the temperature of the epoxy resin, whilst monitoring the ambient and pipe temperatures.

Creating your own climate-controlled wet-out area is a good way to control the temperature of the resin– such as creating a tented area or using the inside of a van or trailer. However, when time is money, you may want to consider investing in a UV CIPP lining system when you’re up against challenging ambient conditions and tight deadlines.

Infused with a resin that only sets under ultraviolet light, UV CIPP liners are different to your traditionally cured liners as the resin in the liner cures under UV-light from a light train which travels through the pipe. UV lining is quicker and greener as it does not produce any by-products like hot-curing does. Providing long-lasting repairs to sewers and pipes without the need to excavate, UV also requires less equipment, so site set-up and take-down are quicker, making it especially suitable for busy locations like roads, railways and airports, or for those tricky access sites where there is limited room to manoeuvre. (Check out our best-selling UV & LED Lining systems from I.S.T's Starlight and Brawo® on our website)

You’ll already know that when the weather turns cold, rodents will be finding a place to keep warm and with plenty of food sources. Yes, that’s right. Drains are the major source of food and water attracting rats to invade properties. So don’t forget your everyday essentials and have rat blockers for drains. You can get eco-friendly and humane rat blockers to install in drains to prevent rats from entering the property using its one-way valve system. Or, you can solve two problems with just one fixture with our non-return valves to stop water and deter rats!

With variable weather conditions to consider and a variety of curing methods available across the sewer and drainage repair market, as contractors, you are provided with several applications to tailor your No-Dig solution to each specific job. Each has its strengths and limitations but are all still worthy methods to fix a pipeline repair. For more info and advice on which curing systems are most suitable for you, or if you are in need of your everyday drainage supplies get in touch with the S1E Sales Team on 01226 397015 or email contact@s1e.co.uk.